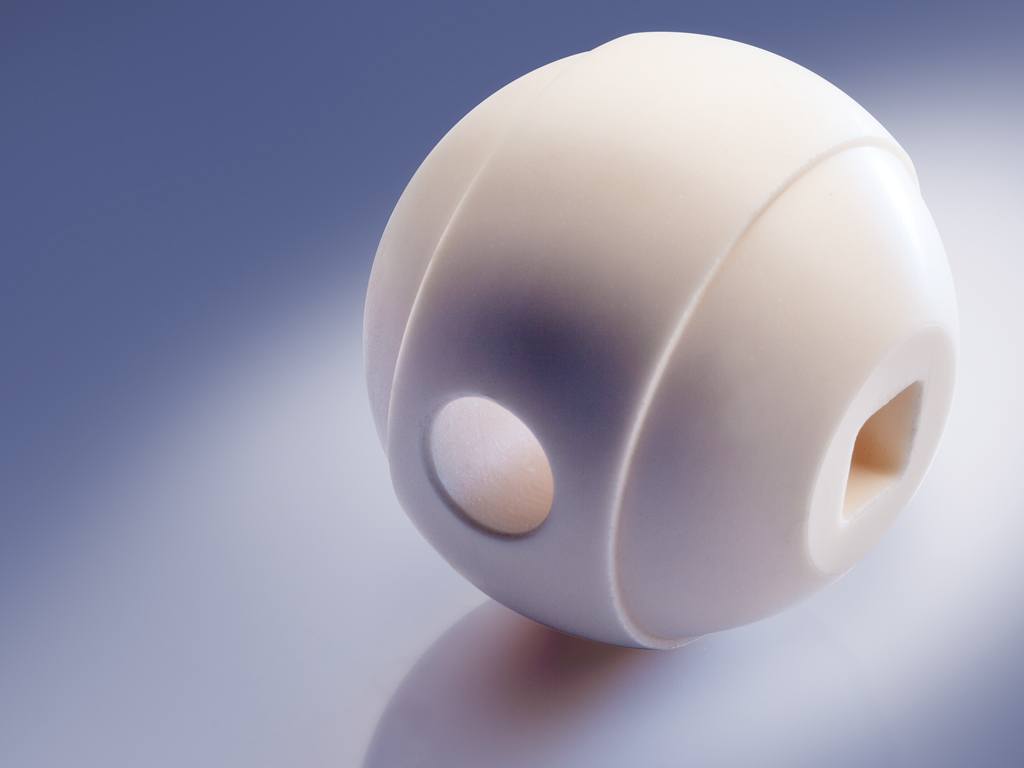

The manufactured assemblies and ceramic components from BCE cover a very broad spectrum in various fields of applications and several industry sectors.

Show ApplicationsFounded in 1986, BCE Special Ceramics has been a leading manufacturer of technical ceramics for over 30 years, known for precision, high-quality ceramic materials, and reliable manufacturing technology „Made in Germany.“ We produce custom ceramic components in batch sizes starting from 1, using premium oxide ceramics such as aluminum oxide (Al₂O₃), zirconium oxide (ZrO₂), and their mixed oxides ATZ (Alumina Toughened Zirconia) and ZTA (Zirconia Toughened Alumina). Choosing the right ceramic material is critical and an integral part of our comprehensive consultation. Our technical ceramics are distinguished by superior material quality, excellent precision, and customizability – ideal for demanding industrial applications in fields such as mechanical engineering, electronics, medical technology, and aerospace. In addition, our flexible production enables rapid prototyping before full-scale production.